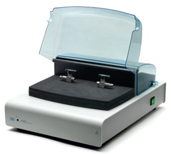

Oxitest Reactor

OXITEST

OXIDATION TEST REACTOR

The Oxitest is an innovative solution, entirely controlled by the powerful OXISoft™, able to provide high quality, added-value information concerning oxidative stability in foods, oils and fats.

The Oxitest works directly on the whole sample without the need for preliminary fat separation, and is suitable for the determination of the quality and the state of preservation of the food sample.

An extremely simple and intuitive instrument equipped with two separate titanium chambers in order to analyze the same sample in duplicate or different samples at the same time and under the same conditions. The stability of the sample is determined by accelerating the oxidation process using high temperatures (from 20 to 110 °C) and a pre-determined oxygen pressure. Oxygen is consumed during fat oxidation and it is this decrease in oxygen pressure that enables us to obtain useful information concerning the food sample. The intuitive software controls the entire process in a user friendly way and the operator can record data in a database, compare tests, export the data to an Excel file, filter and order the data quickly and simply.

The Oxitest is the versatile VELP solution suitable for a wide range of applications including :

- Prediction of the oxidation stability during shelf-life studies, by analyzing the product at defined time intervals and building an experimental curve;

- Evaluation of the adequacy of storage conditions;

- Evaluation of the best packaging solution;

- Comparison of the oxidation stability of different formulas for food preparations;

- Evaluation of the oxidative stability of vegetable oils of different botanical origin;

- Evaluation of the effectiveness of antioxidant;

- Information on product oxidation when the oxidation flex is not visible, especially for products with a low fat content (4 - 5%). In this case, product oxidation can be achieved by combining the Oxitest with the gas chromatographic technique.