Reactors

CondenSyn Air Condensers

The Asynt CondenSyn Waterless Air Condenser is a unique glass condenser, handmade individually in the UK, that requires no cooling water for operation. By using a unique glass forming technique we have been able to manufacture a high surface area air condenser which is robust and effective. CondenSyn is available to suit any standard size connection with B19 also very popular.

Every CondenSyn is individually handmade in the UK.

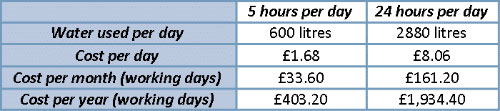

Saving money and water :The average rate of water used in a condenser is 2 litres per minute; this rate was confirmed by a major UK research institution as the average measured use per water condenser in their facility. The water costs used below are at £1.22 per cubic metre supply and £1.56 per cubic metre waste which is equivalent to 0.28p per litre. This commercial rate cost is from a water supplier here in the UK, Anglian Water in March 2020.

DrySyn Range

Heating blocks provide a safe, convenient and productive alternative to heating mantles and oil baths for heating round-bottomed flasks, tubes and vials. Used in combination with a standard hotplate stirrer, heating blocks such as the Asynt DrySyn® range have proved themselves with their ability to outperform the heat-conducting properties of oil baths.

DrySyn Range consists of :- DrySyn Single Position Blocks

- DySyn Multi Position Blocks

- DrySyn Low Temperature Range

- DrySyn Reactors

- DrySyn Overhead Stirring

- DrySyn Customized Solutions

fReactor Flow Chemistry Platform

Asynt has collaborated with the University of Leeds to bring to market their exciting new flow-chemistry platform – the fReactor Classic.

Designed by chemists and engineers from within the Institute of Process Research and Development the fReactor Classic is simple to assemble and modify, making it suitable for a wide range of continuous-flow processes. Integrating the efficiency of pipe-flow processing with the advanced mixing of a CSTR, the fReactor Classic delivers a general “plug-and-play” setup which is well-suited to multiphasic reactions.

High Pressure Reactors

Single Position High Pressure Reactor

From 5 ml to 50 litres, custom made to your exact requirements .Materials of construction, always a critical factor in the design equation, include stain less steels – super duplex, 316 and 321 to name but a few for most standard units, and a wide variety of other grades for special duties: Ferralium, Hastelloy, Monel, Inconel, Incoloy, Nickel, Nimonic alloys, Titanium, Zirconium and alloy steels.

Multi Position High Pressure Reactors

Designed to be used in conjunction with a simple bench top magnetic stirrer or stirrer/hotplate. The Asynt Multicell Parallel High Pressure Reactor is a cost effective lightweight unit fabricated in 316 Stainless Steel suitable for numerous stirred or non stirred applications. These include hydrogenations and applications where air sensitive materials are used or any other reaction where pressure or temperatures are required.

ReactoMate Lab Reactors

ReactoMate consists of CLR Reaction systems that are fully customisable to the users requirements with an extensive range of options, Static dissipative PTFE reactor accessories, ReactoMate Datum Support which are suitable for vessels from 100 mL to 5,000 mL, this support allows you to replace multiple reactor setups with one versatile and reliable system. The system also has options like Reacto-Mate Jacketed Reactors, ReactoMate Baffle Systems, ReactoMate QUANTUM Support etc.

Flow Chemistry

Designed by chemists for chemists, FlowSyn makes flow chemistry accessible to novices while at the same time catering for highly complex reaction protocols. Start with a standalone FlowSyn system and simply upgrade as the need arises by choosing from comprehensive range of systems, material options and reactor modules